Cool-headed technology from a region so beautiful that you can’t help but fall in love with it. These two factors are more closely linked than you would ever guess. Join us in Norway – on a visit to Electrocompaniet’s headquarters in tiny Tau in the bay of Stavanger.

Visits to manufacturers are usually focused on new products or “things to come”. The true background to such trips is, of course, completely different: personal contact with the country and its people gives a lasting impression of what makes the people behind the brands tick, what drives them and why their components sound the way they do. Rarely have I experienced such a surprise as with Electrocompaniet. The team lives and works in a fascinatingly beautiful environment, devising technically precise, sometimes coolly calculated circuits that bring a balance and musicality to the listening room that you only get from very few brands. And precisely this is another impressive aspect: starting with company founder Per Abrahamsen, through the interim Managing Director Mikal Dreggevik to the current team, EC has undergone countless changes – and yet has always remained true to its core.

It is not always easy to deal with this legacy, explains long-time developer Geir Svihus. He is responsible for amplifier circuits and “all things analog”. He often comes up with ideas on how this or that aspect of the components could be implemented much more efficiently. But then there are discussions about whether the redesigned circuit still sounds like an Electrocompaniet. After such discussions, the Norwegian usually grabs his jacket and hikes a few kilometers to the next summit. “I just walk up a mountain,” he smiles. Right next to the company building of Westcontrol Holding, EC’s parent company, is one of his favorite destinations. The rocks, the forest and the breathtaking view over the huge bay of Stavanger help him sort his thoughts.

With this anecdote in mind, we move on to the second item on the agenda. Sales Manager Lasse Danielsen has planned a road trip – as an official part of the company visit. We stop off at Norway’s only vinyl pressing plant (more on this at a later point) and at the “Swords in the Mountain” on the Hafrsfjord. Harald Fairhair laid the foundation stone for Norwegian unification here in the 9th century by sending the fleets of several hostile tribes to the bottom of the sea. A short time later, we are on our way to the seclusion of the mountains. After a two-hour drive through breathtaking scenery, we reach the eastern end of the famous Lysefjord – one of the most famous spots can be seen on the homepage of the German EC distributor MRV. From there, a small car ferry took us back to Stavanger. Finally, it was time for a city tour: colorful wooden houses and the exuberant atmosphere of the harbor district form a strangely harmonious contrast to the omnipresent oil industry (dressed in discreet understatement) – the engine of the Norwegian economy is at home in Stavanger. The tour took a lot of time, but it was important to him, explains Lasse Danielsen. The surrounding area is part of Electrocompaniet. Many of Westcontrol’s employees, such as Bjorn Kindingstad, the CEO of EC, have houses by the small mountain lakes where they spend a lot of time. In everything they do, the Norwegians try to stay down to earth and remember their roots.

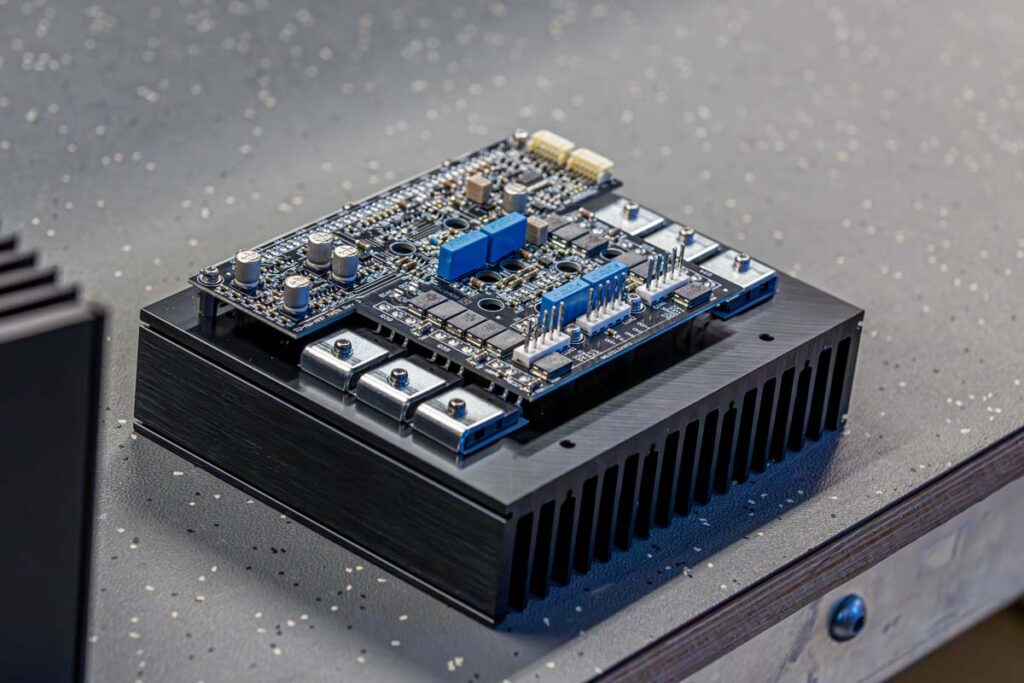

And it is precisely this reflection that preserves the unmistakable charm of Electrocompaniet, explains Geir Svihus. He has just developed a new generation of amplifiers. We have already introduced you to the AW 800 in FIDELITY 70, and the AW 300 mono version is currently on sale. Both amps have been redesigned from the ground up and have achieved a level of manufacturing precision that sets new standards. This is primarily thanks to the close cooperation with Westcontrol. The company specializes in PCB assembly and the assembly of complex technologies. On a tour of the building, we spot, among other things, a small “robot” that was developed as a companion for sick children. Although the circuit board experts do not interfere in Electrocompaniet’s affairs, they are on hand to offer advice when it comes to increasing production efficiency. The two power amplifiers have a modular design. The 800 and 300 are not only based on identical principles, but are also made up of the same components. Technical Director Volker Hunger explains to us that this is the only way to guarantee another characteristic of the brand: despite the quality of workmanship and sound, EC components have always been fairly priced. The fact that the new power amplifiers make a considerable leap upwards is simply due to the fact that the Norwegians had to take a longer break from amplifiers due to the complex development of their EC Living family.

The concept of both amps still follows the principles of the founding fathers. Per Abrahamsen worked closely with the Finnish theorist Matti Otala, who discovered and mathematically described the so-called TIM distortion (Transient Inter-Modulation). EC had already set its sights on intermodulation when other manufacturers were not even aware of the term. Abrahamsen’s ideal was an “amplified wire”, a signal that is converted into power current without any intervention in its quality. This principle can still be found in the device descriptions today: “AW” stands for “AmpliWire”.

In conversation with Geir Svihus and Volker Hunger, who is responsible for all digital developments, we quickly come to the omnipresent development constraints: The distributors and markets demanded ever new products, which is sometimes absurd: after all, a fully developed integrated amplifier from 2007 still makes music at a competitive level today. And so the EC team, which is essentially just four people, meets the pressure with Norwegian calm and concentration: the two power amplifiers form the start of a new Classic family. Next up is a preamplifier, a successor to the EC 4.8 MKII, which will probably be launched before the end of the year. Then all the basic components will be in place to modernize the integrated amplifier fleet in comparatively quick succession. Volker Hunger explains that this is the only way the small team can meet all requirements.

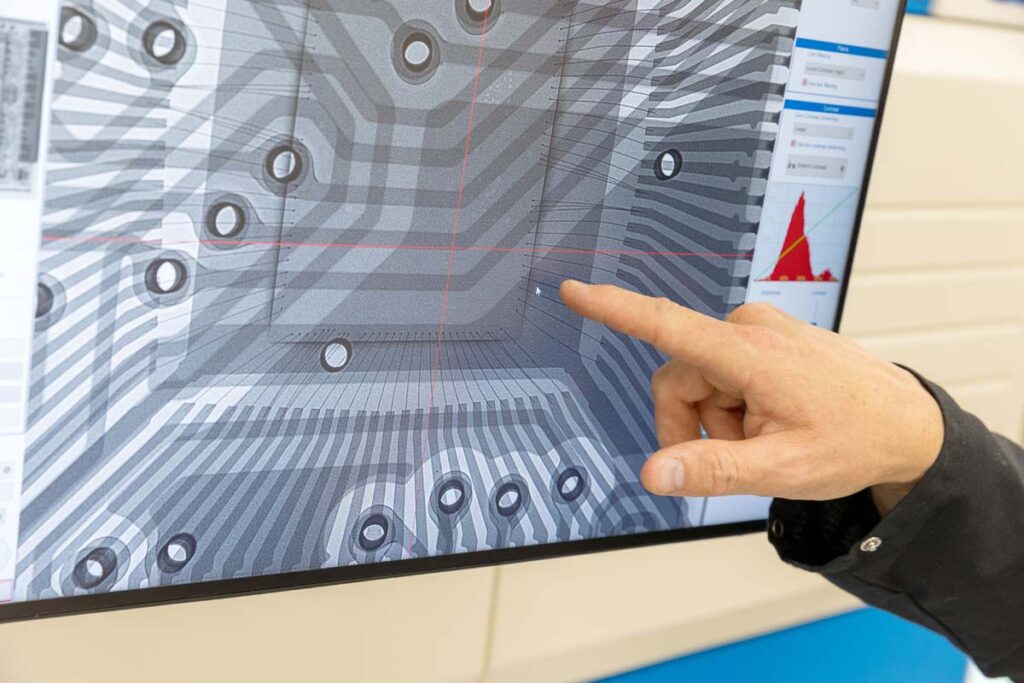

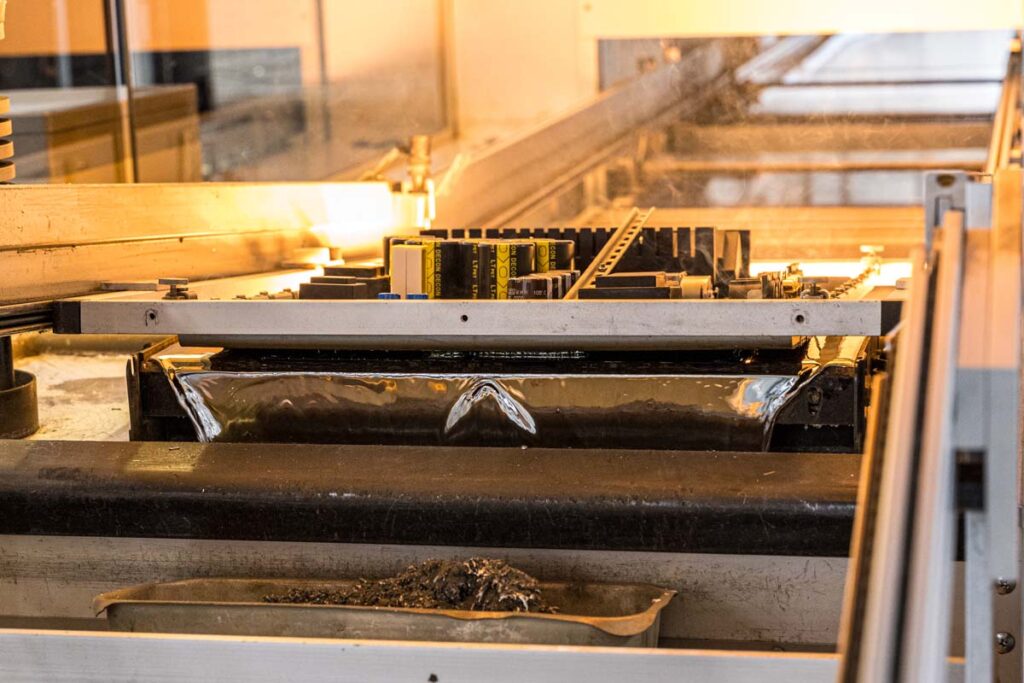

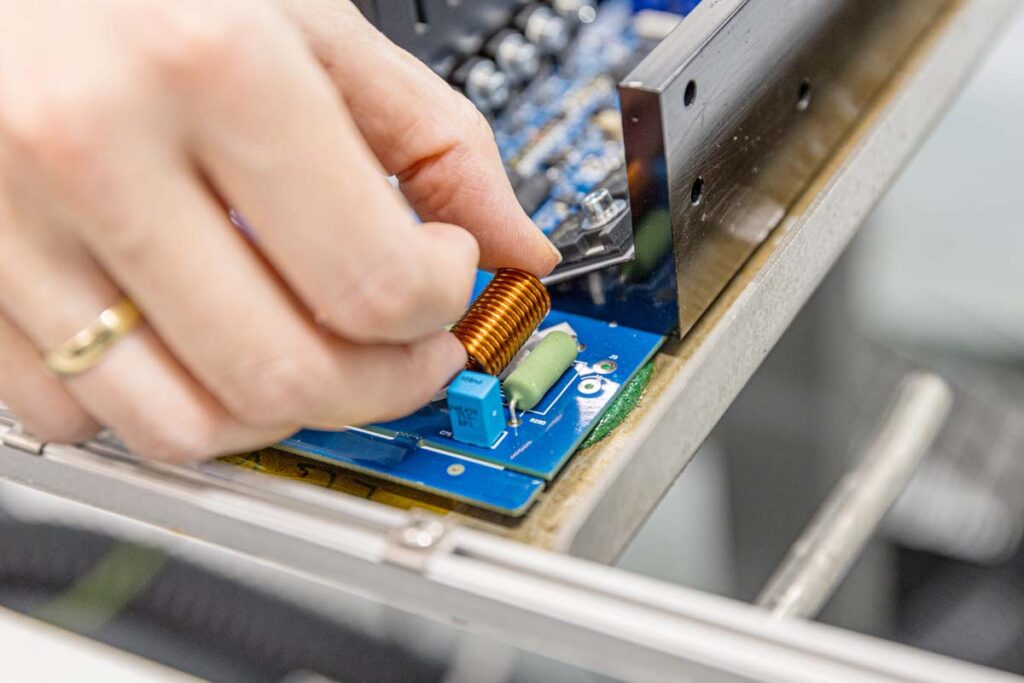

On our subsequent tour of the Westcontrol production facility, we are amazed at the efficiency with which the company works on many different products at the same time. We start with a huge parts warehouse, where we discover countless components and small rolls of “component tapes”. Main circuit boards for the ECI 6 DX MKII integrated amplifier model are currently passing through one of the meticulously coordinated assembly lines. Tiny mechanics, electromagnets and lasers are used to place components on the boards, which I cannot see with the naked eye. Only then is it the turn of the “rough” structures. We witness how a team of employees positions electrolytic capacitors and coils on the ECI boards before they pass through a soldering machine. At the end, it’s the turn of quality control. The finished circuit boards are put through their paces in a course of visual inspections and metrological checks. Because Westcontrol takes it very seriously, the company purchased a huge X-ray machine with an almost ludicrous magnification function. Production manager Torfinn Fiskå shows us the finest structures on one of the monitors and explains that the image shows the conductor paths of a processor in the D/A converter of the ECI 6 DX.

Finally, we visited a small factory hall where dozens of amplifier modules are waiting to be assembled; these are the Electrocompaniet AW-300 power amplifiers. With their long plug-in contacts, the modules basically just have to be plugged into the prefabricated housings, which are already ready with power supply units and transformers. Perhaps there’s a pair among them that we should definitely try out in our listening room …

MRV Audio – Inh. Matthias Roth

Vertrieb für Electrocompaniet und EC Living

Hauptstraße 14

82467 Garmisch-Partenkirchen

Telefon +49 8821 7309958

info@mrvaudio.de