Do it with style or don’t do it at all! – That’s how you could sum up the motto of Norway’s only vinyl pressing plant. The T-Time Vinyl Plant in Stavanger meticulously produces sound media by hand. But it’s not just the records –the premises of these people of conviction are equally fascinating.

It feels like we are traveling back in time. Our small tour group enters the production room of the T-Time Vinyl Plant via a side entrance. The company is located on the first floor of an old factory that has been converted into a kind of cultural and art center. The path leads us through a quaint pub and into a bright workroom with two hissing monsters. Sigve Håland and some of his employees greet us in their typical work clothes: The team looks like they’ve just arrived at the yard in a Model T – at a time when the legendary car was still rolling off the Ford assembly lines. The unmistakable style of the employees matches what they do: T-Time is Norway’s only vinyl pressing plant, although the term vinyl factory would probably be more appropriate. One of the pressing machines, which looks almost as historic as the aforementioned Ford model, is in the process of piling up a respectable mountain of bright yellow records.

Customers usually order their records in batches of thousands, the owner explains under the sullen gaze of the T-Time mascot Ruby. The simple reason for this is that the strained pressing mold then shows the first signs of wear and tear and further records show an increasingly significant loss of height. He is currently pressing just such a thousand. Håland holds out a handful of yellow granulate to me before throwing it into a heated press, which molds measured portions of the granulate into hand-warm, soft vinyl tablets. He hurriedly places them on the massive platter of his mysterious apparatus and – pfffsss – a record is pressed, in this case a Norwegian pop compilation. Even before the press opens, the platter performs a 360-degree rotation while a small cutting stylus cuts off the excess material. The offcuts are then ground and returned to the cycle. In one swift movement, Håland removes the fresh vinyl disc, inspects it carefully from both sides and places it on a storage pile. Several dozen records are already stacked in pairs on top of each other to cool and harden before a flat metal plate is added as an intermediate layer, which also serves as a weight and heat conductor to prevent the records from becoming wavy as they cool.

The two T-Time presses are barely visible under a tangle of hoses, cables and insulated pipes. They are almost as historic as the employees’ clothing and date back to a time when vinyl was the only mass medium besides cassettes. Their age doesn’t detract from their pressing quality, though: lovingly maintained and equipped with countless modifications, they work as precisely as on the first day. However, inspecting the sensitive machines takes a lot of time. Normally, therefore, only one of the presses is working, as was the case during our visit, while the other is being checked and readjusted.

The bright yellow vinyl gives me the idea to ask the expert about the differences in the sound of colored vinyl. There is definitely something to it, Håland explains. Vinyl is transparent, while carbon (or rather: carbon dust) is added to the famous black version. This has a dampening effect, which is why the black material mixture simply sounds best. Colored pigments are added to the other shades – and generously at that, if it is to shine as wonderfully as the yellow LPs in front of us. This changes the structure of the vinyl and naturally has an impact on the sound.

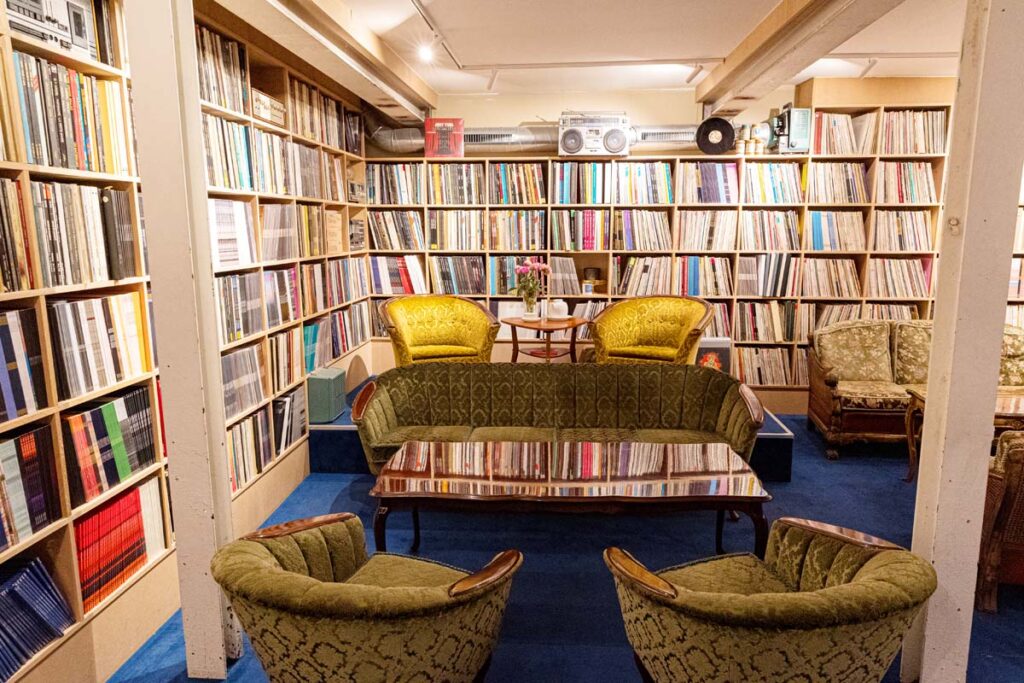

Nevertheless, he understands that his customers are increasingly interested in this kind of eye-candy. Labels and artists have to charge a lot of money for records these days to even come close to covering their production costs – so the product might just as well look the part, too. In a room next to the production room, we see the current selection: A small case with granulate samples displays T-Time’s color catalog. Compared to the production area, this room feels like an oasis of calm. It is the Vinyl Plant’s business salon. A cozy listening room whose shelves hold thousands of sound media. Time and again, Norwegian artists in particular come to see the quality of the pressing for themselves. Later in the day, for example, Aurora Aksnes has announced that she has had a new edition of her debut All My Demons ... pressed. An Electrocompaniet system, which has just been upgraded with two AW 300 monoblocks, is available for listening, as EC sales manager Lasse Danielson explains.

By the way, booking a pressing is really easy: you can simply place your order on the Vinyl Plant homepage. And then you should be patient – T-Time is mercilessly fully booked and is therefore currently looking for a third press. “Don’t call us, we’ll get back to you …”, the message on the homepage reads.