Børresen, Aavik, and Ansuz are fledgling brands, however the exclusive Danish products are the result of three decades of experience, research, and findings as well as some amazingly innovative approaches.

“The British first cottoned on to it during World War II,” Michael Børresen stated in the production room at his company, where the several tables dotted around us were filled with employees busy soldering cables, fitting circuit boards, and preparing assemblies. “Their radar planes should have actually been faster and more effective at discovering enemy U-boats,” he continued. “Several thousand meters up high in the sky, they had all the cards stacked in their favor.” Theoretically yes, but the reality was quite different: “Destroyers down below, on the water, actually turned out to have the best noses for sniffing out U-boats,” he said, waving his fingers in front of his face.

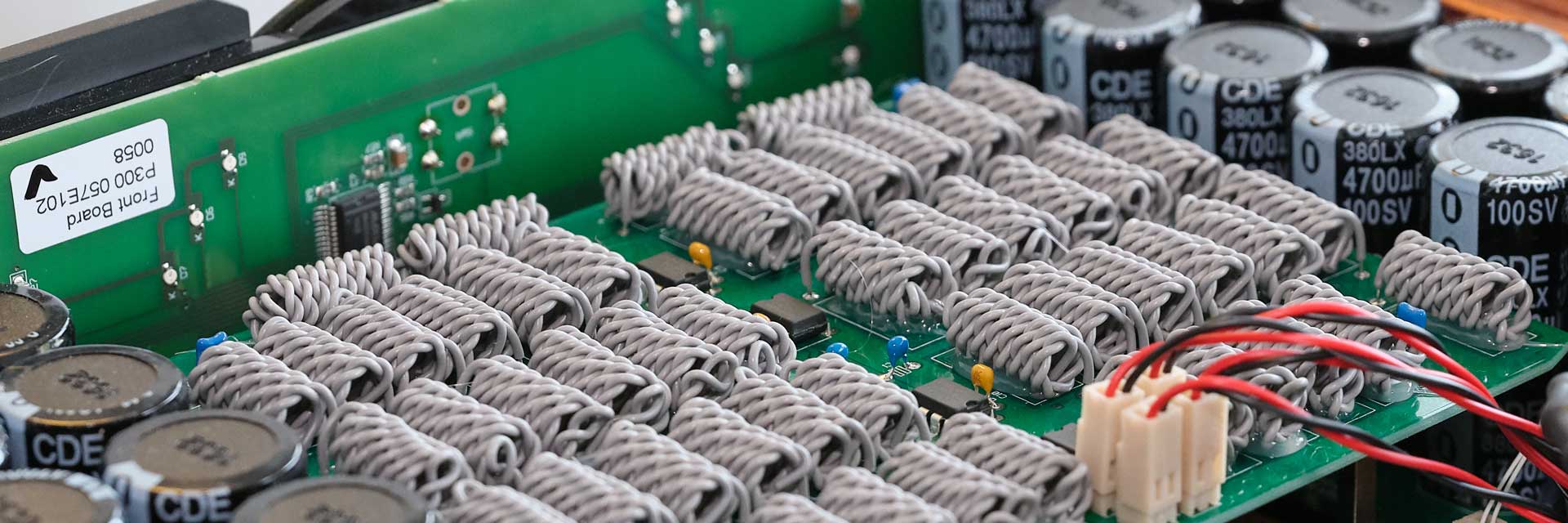

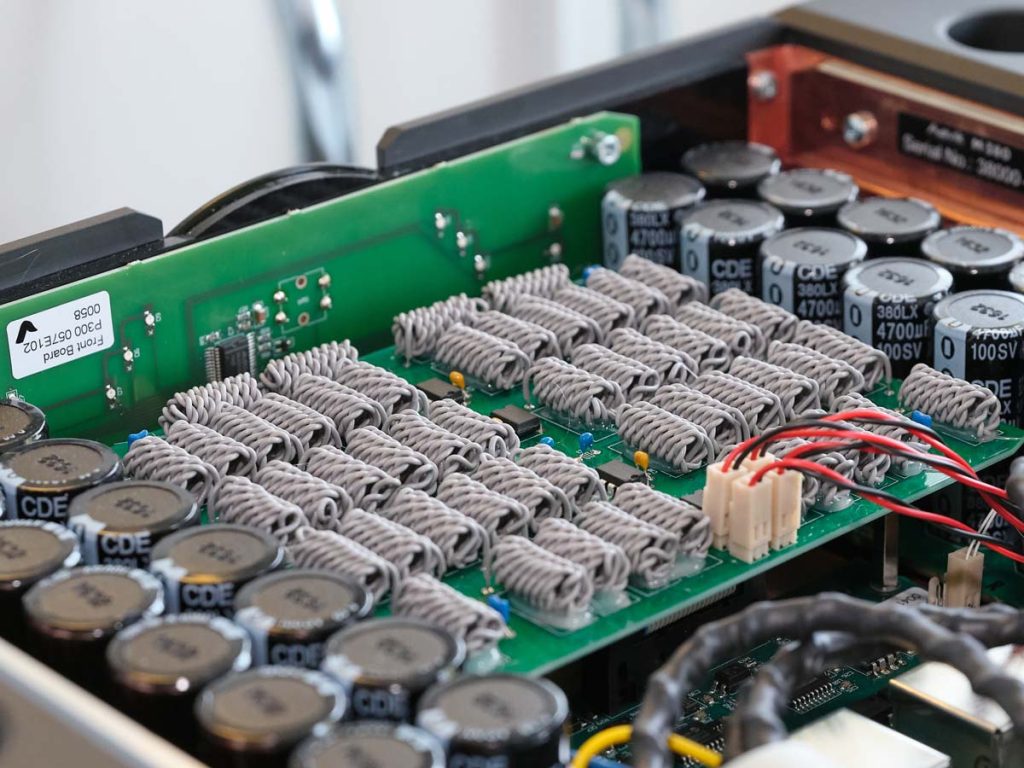

On the workbench in front of us I spotted a striking and strange-looking construction: an open Aavik P-300. The relatively compact power amplifier had two opposite-facing rows of large filter capacitors. Nothing out of the ordinary so far. But in between those rows, arranged on a separate circuit board, I could see a whole armada of spiral-twisted cable sections. “Researchers ultimately discovered that it all came down to the incessant, unrelenting waves of the Atlantic,” Børresen explained. “Ships continuously bob up and down on the water whilst planes glide forwards straight through the air.” Børresen began to wave his hand in front of his face again. “Waves create modulation, which in turn ensures the ship’s radar continuously changes its position and, to a certain extent, its angle of view. It’s similar to holding my hand in front of my face: If I hold it still, my fingers obscure part of my field of vision; but if I constantly move them up and down, I see everything. I receive all the information. And that’s precisely what sets our electronics apart.”

We had arrived at Aalborg Airport not three hours earlier. If you briefly set aside that Greenland is part of the Kingdom of Denmark, you could say that the idyllic city of Aalborg is located at the northernmost tip of Denmark. Lars Kristensen had picked us up after our flight and taken us straight to a restaurant tucked into a picture-perfect location on the Limfjord: to our left a marina, to our right a view of a drawbridge, and in between our little eatery with its bustling terrace.

Three years ago Kristensen became the co-owner and sales director of the trio of companies Børresen Acoustics apS, Aavik Acoustics, and Ansuz Acoustics. And he’s a born salesman, that I can attest to from my own experience. When I attended my first-ever HIGH END, which must have been back in 2001, I found myself watching a demonstration by Nordost pretty much as soon as the doors had opened. Kristensen had held a similar sales role at Nordost at the time. Not more than five minutes had past at that demonstration and I became totally convinced I absolutely needed a Valhalla loudspeaker cable in my life or else it wouldn’t be worth living. Today, though, he was recommending something less expensive, but every bit as capable of hitting the spot: Grimbergen, which we thoroughly enjoyed. Ironically, not a Danish beer, but Belgian.

The year after we had first met, Kristensen joined Børresen’s company Raidho Acoustics. Together, Kristensen and Børresen really made waves, causing a stir in the high-end segment with their exquisite fleet of speakers. But then in 2017, some differences of opinion led to the two founders leaving their company and taking some of their team with them. From then on, they’ve dedicated themselves to the “holy trinity” of their new full range: Børresen for loudspeakers, Aavik for amplification and lastly Ansuz for cables as well as all necessary accessories. In fact the only thing that they’ve never dabbled in and have left for others to perfect is source devices.

“Why three separate brands?”, we asked. “There are two reasons,” Kristensen explained: “Firstly, it provides a safeguard. If one of the three divisions doesn’t go as planned, we can pull the plug on it without it affecting the other two unnecessarily. And it’s also designed to make a statement. Our products do, of course, complement each other exceptionally well and are designed to work together. But you could also operate an Aavik amplifier with non-Børresen loudspeakers — and vice versa. The different brand names are there to remove any obstacles that might prevent people from accessing our exclusive range of products.”

We had hardly said cheers and clinked our glasses when the man who had lent his name to the speaker company walked into the bistro. Michael Børrensen extended us a warm welcome, sat down, ordered his food, and got straight down to business by waxing lyrical about capacitors, amplifier circuits, and chassis and loudspeaker designs. His technical descriptions went into such depth and complexity that I kicked myself for having left my notebook in the car. Not because I wanted to take notes, but because I wanted to give him the opportunity to illustrate exactly what he was talking about by making a few sketches. But in the end, there actually proved to be no need. As the description at the beginning of this article indicates, he’s one of those developers who dedicates his time to solving practical problems and challenges and who can describe the technology he uses so well that he helps his listeners to conjure up vivid mental images. Despite having been on our feet since 4 a.m. that morning and being pretty annoyed about our outbound flight being delayed, it was an absolute pleasure to follow his extremely descriptive and animated explanations.

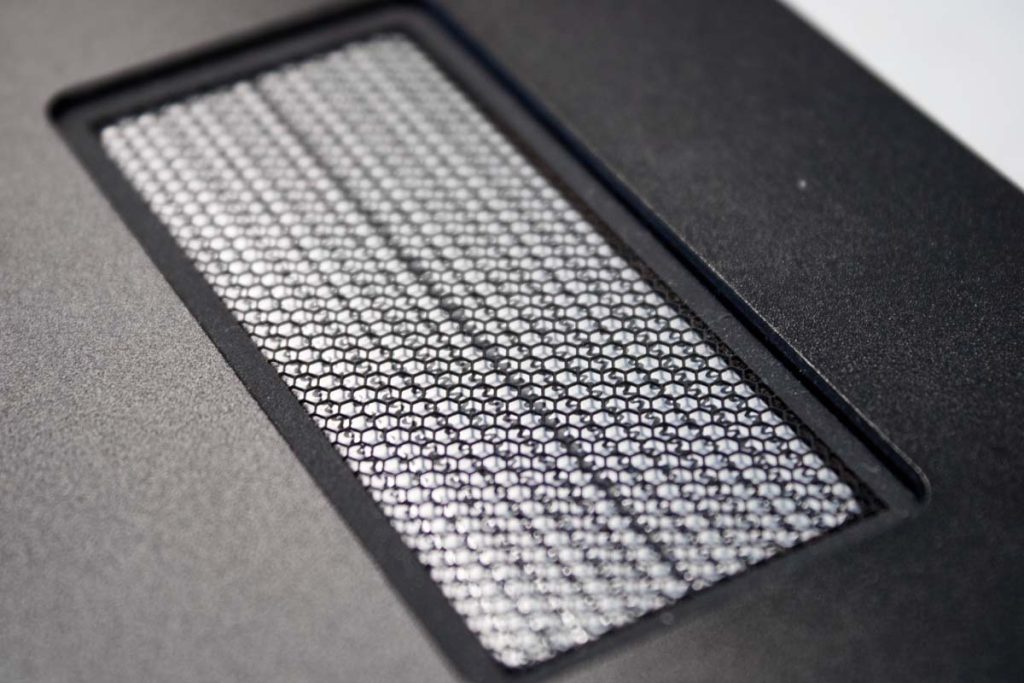

Before lunch (which consisted of some delicious fish) had even been served, we discovered Børrensen designs his chassis without using any iron. A permanent magnet made from the metal would apparently change its behavior depending on the distance to the coil. And since the coil is continuously moving, no constants could be realized. To achieve a more consistent drive, he therefore uses several pricey neodymium magnets that are anchored in a cage made from aluminum and other nonmagnetic metals. The housings of Børrensen’s loudspeakers are also equipped with an innovative bass reflex port. Instead of one large cross-section, they have several small outlets that hold small tubes of varying lengths. “This enables us to break up the bass port’s resonance and, instead of one single problematic resonance, obtain several small resonances that are way above the operational range of the reflex port,” he explained. Børresen’s slogan, “Re-Think Loudspeakers,” truly seems to be a passion.

And his understanding of vibration is pretty much second to none: Børresen studied engineering in Aalborg, even majoring in resonance and vibration patterns, before later also putting his knowledge to good use for innovative developments outside of the hi-fi industry. The aim of his development work, he explained to us, was to better understand and control the resonance behavior of loudspeakers and devices. Resonance can’t be avoided, so developers need to ensure it takes place in frequency ranges in which it can’t cause any harm. This, of course, requires extensive knowledge of how the materials being used behave. We’d soon find out the level of detail involved Børrensen’s research into materials.

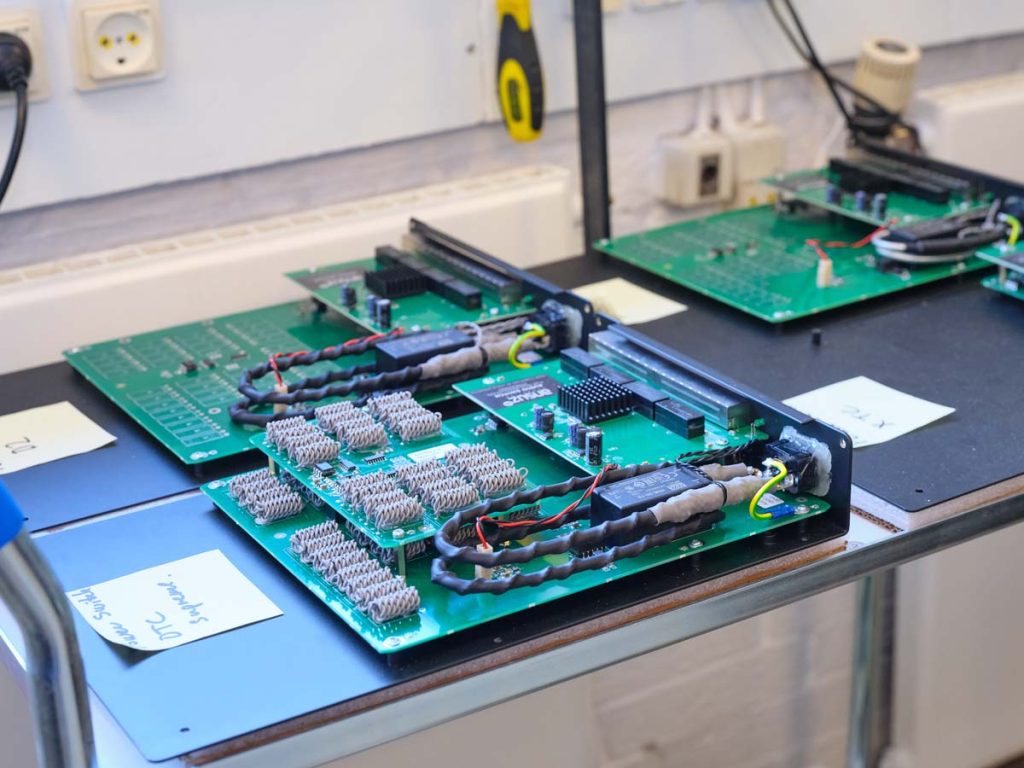

But first, a tour of the company headquarters, a building located in the southern outskirts of Denmark’s northernmost city: It’s clear from the way the space was divided up inside that this was a company — sorry, three companies — that have quickly outgrown themselves since being founded not all that long ago. The main entrance led straight into a well-structured shared office space where the development, sales, marketing, and distribution work was all being carried out at just four desks. Through a door on the left, we reached the compact electronics production room where we had the opportunity to see the half-assembled P-300 mentioned earlier. The numerous mouse-gray cable sections caught our attention… whereupon Børrensen launched into his interesting World War II stories:

“The electric fluctuation brings more acoustic information into the listening room,” he said. By “fluctuation” he meant a tiny time axis modulation: The many small coils formed part of an oscillating circuit that would constantly shift signals. “Just to make sure I understand it correctly,” I quickly interjected, stunned at what I was hearing, “the amplifiers create jitter?” “No,”Børresen responded, “jitter distorts the phase and the timing inside a signal. Our circuitry modulates it in its entirety. It jitters on the time axis, but remains unaffected itself.” But one question remained that hadn’t been addressed during our tour: How on earth does someone come up with such a thing?

The circuity isn’t only being used in the amplifiers. It soon became clear at one of the other workstations that Børresen also incorporates it (admittedly in a different form) in cables and power distributors and in the new Ansuz LAN switches. Each of the little cable coils has been cut to length, twisted, wound, and welded onto the circuit boards by hand in the production room. Depending on the device in question, this could involve several hours’ work. We’d never come across components, signal cables, or loudspeaker cables involving more intricate craftsmanship.

We returned to the office space. Another door led into a small warehouse and then on to the chassis production area. Børresen not only had worked as a developer for his previous company Raidho, he also develops drivers and loudspeakers for Scansonic. Anyone familiar with the models produced by the three small-scale manufacturers will immediately be able to spot similar visual characteristics. In fact, there’s also significant crossover in terms of the technology involved. All loudspeakers use ultralight ribbon diaphragms as tweeters. The rest of the chassis are made from an extremely rigid composite material that’s also as light as a feather.

“Such powerful drivers wouldn’t have been feasible 20 years ago,” Børresen said as we inspected a few finished units. Despite their similarities, each of the three brands is distinct. “The indentation on the side of the Børresen loudspeakers was inspired by the BMW M Series models,” revealed Kristensen as we spotted one of the large top-of-the-range models in the warehouse. The Bavarian cars have a similarly shaped opening right by the fender, next to the doors. Incidentally, it not only looks great — at the front edge of the recess sits the multiflowport. Our tour wasn’t over yet though. “A while ago, we rented another wing of the building, which we’re currently converting,” Kristensen stated. We exited the small warehouse and entered an enormous room that would one day become the main warehouse. An unimposing door led us into the impressive in-house listening room. Once there, both gentlemen invited us to make ourselves comfortable on the large sofa.

Kristensen then stated a system’s various components should be considered as a whole. Amplifiers, players, loudspeakers, racks, and cable supports, for example, all add resonance, alter the existing patterns, and influence the behavior of the entire playback chain. To demonstrate that, we treated ourselves to some Billie Eilish on vinyl. The amplifier in use was the Aavik U-380, which drove the Børresen 03 2.5-way floorstanding loudspeakers. In the blink of an eye, a deep thudding, thunderous bass had put us fully under its spell. After just a few seconds, the young singer’s voice sounded holographic, natural, and so beguilingly deep and vivid in the listening room that you would’ve been forgiven for thinking she was actually there. If the Danes had asked us what improvements we thought could be made to the system, we would probably have helplessly shrugged our shoulders.

The track had hardly finished fading out before Kristensen showed us a small collection of vinyl weights related to the cable lifters and device feet of the Darkz Resonance series. They’re not yet available in the Ansuz range. We asked Billie several times to repeat her performance, and each time we used a different weight. The corresponding quality levels of the other Darkz items have the references A, C, D2, and D·TC affixed to their names to represent the different material compositions — from aluminum and copper through to titanium. The effect of the weights truly blew us away. In clearly discernible gradations, they tightened up the bass and made the playback sound more vivid and neat. They also made the electronic production sound unbelievably natural. We left it at that for the time being…

The following morning, we found ourselves in the new part of the building climbing some stairs we hadn’t even noticed the day before. They ushered us up to a large communal kitchen and a closed conference room. Passing by a large wine refrigerator, the stairwell brought us to another listening room where we continued our listening session. On that second day of our visit, Børresen had another meeting to attend and couldn’t stay with us, but was represented in the smaller of the two test rooms by his compact monitor, the Børresen 02. It was also driven by the Aavik U-380 integrated amplifier, and once again the focus was on the Ansuz accessories. The plausible explanation for this was they could simply be changed more quickly than an integrated amplifier or a loudspeaker.

To kick things off, we indulged in the new LAN-PowerSwitches, relatively expansive network distributors for up to seven devices; port number eight was commandeered by the router. Even the switches are available in four versions that differ on the basis of the materials used and the complexity of their “fluctuation circuitry.” This time we listened to a broader selection of tracks from the in-house demonstration samplers: some Leonard Cohen, Trentemøller, and other well-known artists who represent high-end standards but haven’t been played to death. Our impressions were the same as on the previous day: The impressive performance of the visually stylish and discreet chain got discernibly better with every step taken toward the supreme version of the LAN switch.

The loudspeaker cables were up next: Once again here, Kristensen and his team showcased a whole range of different materials and features, from a straightforward aluminum casing through to the “D·TC wiring version with titanium connector capsules. Also containing the fluctuation circuitry, the latter made the playback sound incredibly open, transparent, and three-dimensional. Above all, the top-level configuration of the chain possessed a sense of naturalness and “swing” that left us completely forgetting the fact we were listening to digital media in CD quality over a computer network. As such, the “additional information” promised by Børresen became tangible. The previous day, he had told us the music has always been there on the CD, you just have to extract it…